Introduction

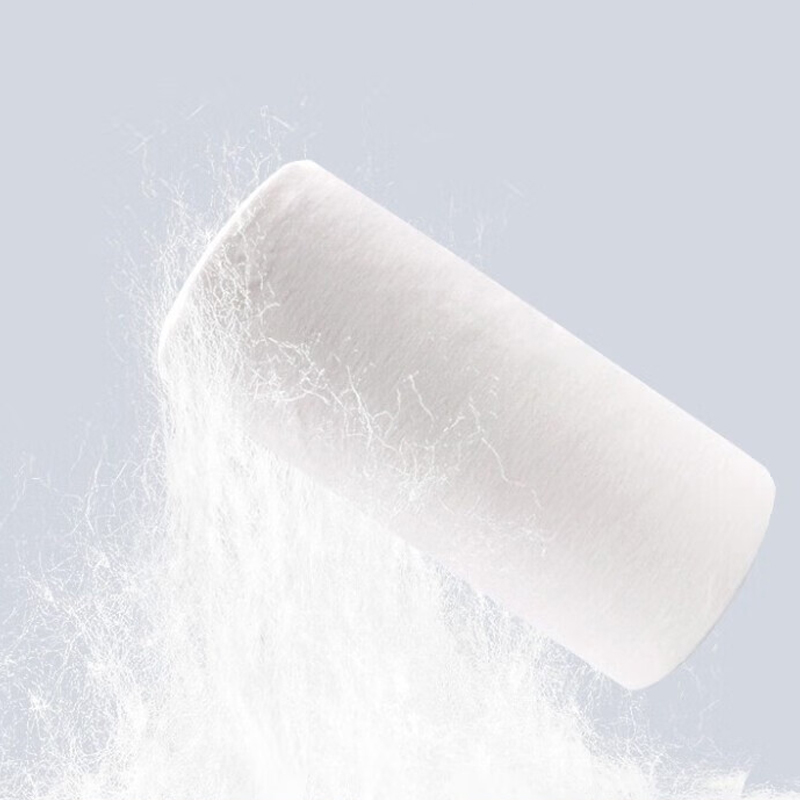

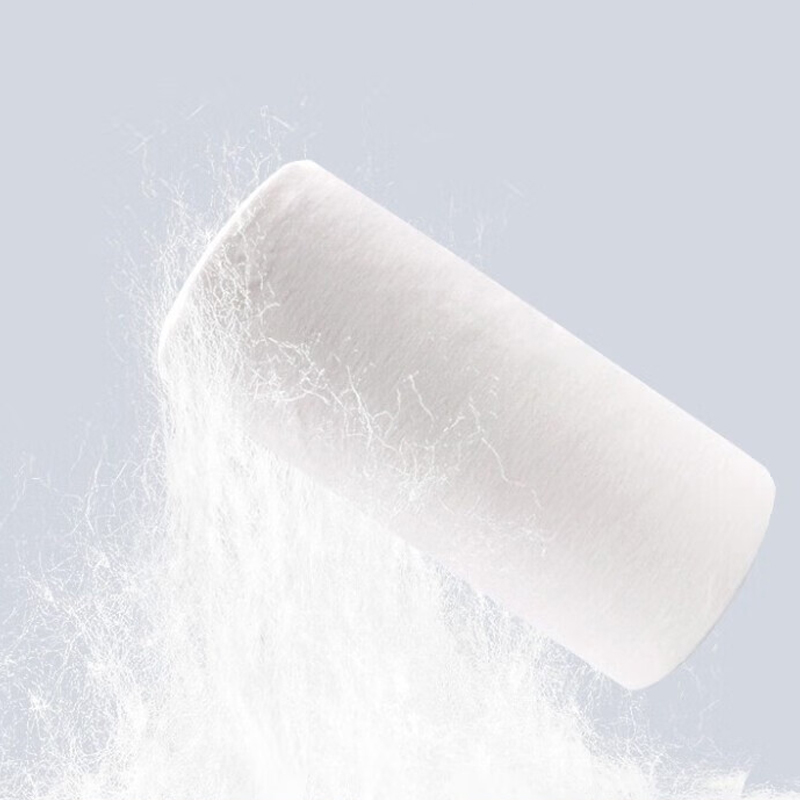

Needle-punched medical cotton is a non-woven fabric that has been gaining popularity in the medical field. It is made by entangling fibers through a needle-punching process, resulting in a durable and absorbent material. Needle-punched medical cotton is often used in wound care, surgical procedures, and as a padding material. Its unique properties, such as high absorbency, softness, and breathability, make it an ideal choice for medical applications. This article aims to provide a comprehensive analysis of needle-punched medical cotton, comparing its market trends, technical aspects, and performance with traditional medical cotton.

Market overview of needle-punched vs. traditional medical cotton

Market size and growth rate

The global medical cotton market has been experiencing steady growth, with an estimated CAGR of 4.5% from 2021 to 2026. This growth can be attributed to the increasing demand for healthcare services, rising awareness about hygiene, and the growing prevalence of chronic diseases. Needle-punched medical cotton, in particular, has gained traction due to its superior properties compared to traditional medical cotton.

According to a report by Mordor Intelligence, the global non-woven fabric market, which includes needle-punched cotton, is expected to grow at a CAGR of 6.2% between 2021 and 2026. This growth is driven by the increasing demand for disposable and hygienic products in the healthcare sector.

Market trends and dynamics

The medical cotton market is witnessing several trends that are shaping its future. One of the key trends is the increasing adoption of needle-punched medical cotton due to its enhanced performance and versatility. Needle-punched cotton is being used in various applications such as wound care, surgical procedures, and as a padding material.

Another trend is the growing demand for eco-friendly and sustainable products. Needle-punched medical cotton, being a non-woven fabric, is considered more environmentally friendly compared to traditional woven cotton. This has led to an increased demand for needle-punched cotton in the medical industry.

The market dynamics are also influenced by factors such as the increasing prevalence of chronic diseases, the growing aging population, and the rising awareness about hygiene and infection control. These factors are driving the demand for high-quality medical products, including needle-punched medical cotton.

Regional analysis

North America dominates the medical cotton market, accounting for a significant share due to the presence of advanced healthcare infrastructure, high disposable income, and increasing awareness about hygiene. The region is also witnessing a growing demand for needle-punched medical cotton, driven by its superior properties and applications.

Europe is the second-largest market for medical cotton, with countries like Germany, France, and the UK witnessing a high demand for needle-punched cotton. The region’s focus on healthcare innovation and the increasing adoption of advanced medical products are contributing to the market growth.

Asia Pacific is expected to be the fastest-growing market for medical cotton, with a CAGR of 6.5% from 2021 to 2026. The region’s growth can be attributed to the increasing population, rising disposable income, and the growing healthcare expenditure. Countries like China, India, and Japan are witnessing a high demand for medical products, including needle-punched cotton.

Technical analysis of needle-punched vs. traditional medical cotton

Composition and manufacturing process

Needle-punched medical cotton is made from synthetic fibers such as polyester, polypropylene, and viscose. These fibers are processed through a needle-punching machine, which uses barbed needles to entangle the fibers and create a non-woven fabric. The manufacturing process involves several steps, including fiber opening, carding, needle-punching, and finishing.

Traditional medical cotton, on the other hand, is made from natural cotton fibers. The manufacturing process involves harvesting, ginning, carding, spinning, and weaving. Traditional medical cotton is typically woven into a fabric, which is then cut and stitched into the desired shape and size.

Physical and chemical properties

Needle-punched medical cotton has several advantages over traditional medical cotton. It is more absorbent, durable, and resistant to tearing and fraying. The needle-punching process creates a dense and compact fabric that can hold more fluid and withstand more stress.

In terms of chemical properties, needle-punched medical cotton is more resistant to chemicals and disinfectants. It can be sterilized using various methods, including autoclaving, ethylene oxide gas, and radiation. Traditional medical cotton is more susceptible to chemical degradation and may lose its properties after sterilization.

Absorbency and breathability

Needle-punched medical cotton has higher absorbency than traditional medical cotton. The needle-punching process creates a network of interconnected fibers that can hold more fluid and distribute it evenly. This makes needle-punched cotton ideal for applications such as wound care and surgical procedures.

In terms of breathability, needle-punched medical cotton is more breathable than traditional medical cotton. The non-woven structure allows air and moisture to pass through, reducing the risk of skin irritation and infection. Traditional medical cotton, being woven, has a tighter structure that can trap heat and moisture, leading to discomfort and complications.

Comfort and softness

Needle-punched medical cotton is softer and more comfortable than traditional medical cotton. The entangled fibers create a smooth and gentle surface that is less abrasive to the skin. This makes needle-punched cotton suitable for sensitive areas and long-term use.

Traditional medical cotton, being woven, can be rough and irritating to the skin. The edges of the woven fabric can fray and cause discomfort, especially when used for extended periods. Needle-punched medical cotton, with its smooth and uniform surface, provides superior comfort and softness.

Application and performance comparison of needle-punched vs. traditional medical cotton

Wound care

Needle-punched medical cotton is widely used in wound care due to its high absorbency and breathability. It can effectively absorb exudate and maintain a moist environment, promoting faster healing. The non-woven structure also reduces the risk of infection and irritation.

Traditional medical cotton is also used in wound care, but it may not be as effective as needle-punched cotton. The woven structure can trap moisture and create a breeding ground for bacteria, increasing the risk of infection. Additionally, traditional cotton may not provide adequate cushioning and support for the wound.

Surgical applications

In surgical applications, needle-punched medical cotton is preferred over traditional cotton for its superior performance. It can be used as a drape, sponge, or padding material, providing excellent absorbency and cushioning. The non-woven structure also reduces the risk of linting and contamination.

Traditional medical cotton is not commonly used in surgical applications due to its limitations. The woven structure can release fibers and particles, compromising the sterile field and increasing the risk of infection. Moreover, traditional cotton may not provide adequate absorbency and cushioning for surgical procedures.

Infection control

Needle-punched medical cotton plays a crucial role in infection control. Its high absorbency and breathability help maintain a clean and dry environment, reducing the risk of infection. The non-woven structure also minimizes the release of fibers and particles, preventing cross-contamination.

Traditional medical cotton may not be as effective in infection control. The woven structure can trap moisture and create a favorable environment for bacteria. Additionally, traditional cotton may release fibers and particles, increasing the risk of infection and complications.

Patient comfort and convenience

Needle-punched medical cotton provides superior comfort and convenience compared to traditional medical cotton. Its soft and gentle surface is less abrasive to the skin, reducing the risk of irritation and discomfort. The breathable structure also helps regulate temperature and moisture, enhancing patient comfort.

Traditional medical cotton may not offer the same level of comfort and convenience. The woven structure can be rough and irritating to the skin, causing discomfort and complications. Moreover, traditional cotton may not provide adequate breathability and moisture control, leading to skin problems and discomfort.

Conclusion

Needle-punched medical cotton is a versatile and high-performance material that offers several advantages over traditional medical cotton. Its superior absorbency, breathability, comfort, and convenience make it an ideal choice for various medical applications. The growing demand for needle-punched medical cotton is driven by its enhanced properties and performance, as well as the increasing focus on infection control and patient comfort. As the healthcare industry continues to evolve, needle-punched medical cotton is expected to play a crucial role in improving patient outcomes and enhancing the quality of care.